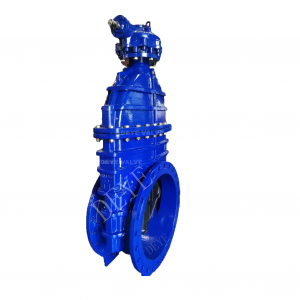

Cast iron ANSI heavy RS Gate Valve GV-H-AF03

Quick Detail:Heavy ANSI 250PSI flanged gate valve with OS&Y

Design standard: AWWA C509 Rising Stem

Body material: ductile iron A536

Wedge: Ductile iron + EPDM

Nominal diameter: 3″,

Pressure: 250PSI 250WOG

End connection: FLXFL flanged ends

Face to face: AWWA ANSI B16.10

Working temperature: -30℃~+120℃.

Test and inspection: API 598.

Gland Gate valve

Red color epoxy powder coated Min. 250 Microns.

Optional Connection: Class 125/150 flange/300LBS

MJXMJ / Flange x MJ / SOCKET Ends X flange

Optional Material: Ductile iron/Cast iron body and bonnet

Optional Seat: Bronze, brass, stainless steel, EPDM

Design: non-rising stem/ Rising Stem

Surface treatment: Fusion bonded epoxy coating red, black, blue

Standard Meets AWWA C515/ AWWAC509/ ANSI B16.34

Size Range; 2″-24″

Pressure Range: 150PSI, 225PSI, 250PSI

AWWA Gate Valves are specifically designed for heavy pressure service. Neck, flanges, and bell are made extra heavy to withstand pipe strain and possible shifting. Body, cover, gates, and stem are built for extra strength, with clean and simple internal construction, to assure long service and low maintenance.

Turning the stem releases the wedging pressure on the gates allowing them to move away from their seats before starting upward travel. Further turning of the stem raises the gates into the fully opened position. When closing the valve, the gates move freely downward without friction, to a position opposite their seats. As the gates approach the bottom of the valve, the iron hooks come into contact with stops which prevent further downward movement of the hooks. The bronze wedges riding on these hooks spread the gates apart and force them against their seats.

Tap water, sewage, buildings, and energy systems for water treatment