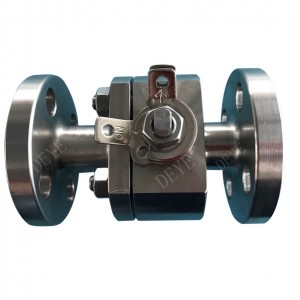

BFV-1004 LUG Butterfly Valve

Quick Detail

Design standard: API 609.

Body material: DUCTILE IRON ASTM A536

Disc Material: CF8M SS316

Seat Material: EPDM

Nominal diameter: 28” DN700

Pressure: CL150 (PN20)

End connection: Lugged for ANSI B 16.9 flange

Face to face: EN558 Series 20

Top flange ISO5211.

Bi-direction Seal, Backup Rubber Seat

Mode of operation: Gearbox.

Test and inspection: API 598. EN12266

Available Body Material: GGG40, GGG50, CS, WCB, SS304, SS316

Optional Seat: EPDM, NBR, PTFE, Teflon. Neoprene

Optional End connection: Wafer, Lug, Flanged.

Optional Body Design: Eccentric or Concentric centerline

Face to face: EN558 Series 13/14, long type or short type

Normal diameter: 4″~96″ (DN100~DN2400).

Pressure range: 150lbs (PN10~PN25).

Available Operation: Gearbox, Electric, pneumatic actuator

Working temperature: -46℃~+200℃.

1. When installing the lug butterfly valve and the pipeline, the flanges on both sides are installed with bolts, so that the valve body and the sealing surface of the valve body are not squeezed by the bolts, which is beneficial to the seal life.

2. The lug can be easily installed in the unwinding position.

3. There is a certain defect in the connection method of the clip. When the bolt is used to install the valve in the pipeline, the bolt squeezes the entire butterfly valve body between the two flanges. The bolt is relatively long, and the resulting creep is also large, which is easy to leak.

It is widely used in petroleum, chemical, metallurgy, hydropower and many other fields