2020 High quality A105 Ball Valve - heavy type threaded 2-pc ball valve with ISO5211 pad BV-1000-01-02-N – Deye

2020 High quality A105 Ball Valve - heavy type threaded 2-pc ball valve with ISO5211 pad BV-1000-01-02-N – Deye Detail:

Quick Detail:

Design standard: ANSI B16.34 or manufacture STD

Body material: stainless steel SS304 SS316

Seat: PTFE, RPTFE

Nominal diameter: 1/2inch.

Pressure: 1000WOG

End connection: NPT FNPT MF /BSP

Face to face: manufacture Length or customized length

Mode of operation: lever Operated

Test and inspection: API 598.

Key Specifications / Features

Reliable sealing performance and small torque;

Full bore and reduced bore;

Low emission packing;

Anti-static and anti-blowout stem design;

Product Range:

Optional Construction: 3pcs, 1pcs, 2pcs body.

Full Bore/ Reducing Bore

Optional Ends: BW, flanged RF FF, NPT, BSP.

Optional seal: PTFE, RPTEF, Nylon, Peek, Metal Seated

Available Body Material: ASTM A216WCB/LCB/CF8M/4A/5A/Alloy Steel

Available Ball : SS304, SS316, Solid Type, A105+ENP.

Pressure Range: 150LBS-1500LBS , PN10-PN250

Size Range:1/ 2”-4” DN15-DN100mm

Optional locking device

Optional ISO 5211 top flange.

Optional Seat:PTFE+GRAPHITE CARBON

Installation:

1)The installation position, height, and direction of entrance and exit must meet the design requirements, and the screw connection should be firm and tight.

2) The handles of all kinds of manual valves installed on thermal insulation pipes must not be downward.

3) The valve must be visually inspected before installation, for valves with a working pressure greater than 1.0 MPa and acting as a shut-off on the main pipeline, strength and sealing tests should be carried out before installation, test standard as per API598.

4) The ball valve with transmission mechanism shall be installed according to the provisions of the product instruction manual.

Application:

used to transport water, steam, oil, nitric acid, acetic acid, oxidizing medium, urea, etc., widely Used in petroleum refining, long-distance pipeline, chemical industry, papermaking, pharmaceutical, water conservancy, electric power, municipal administration, steel and other fields.

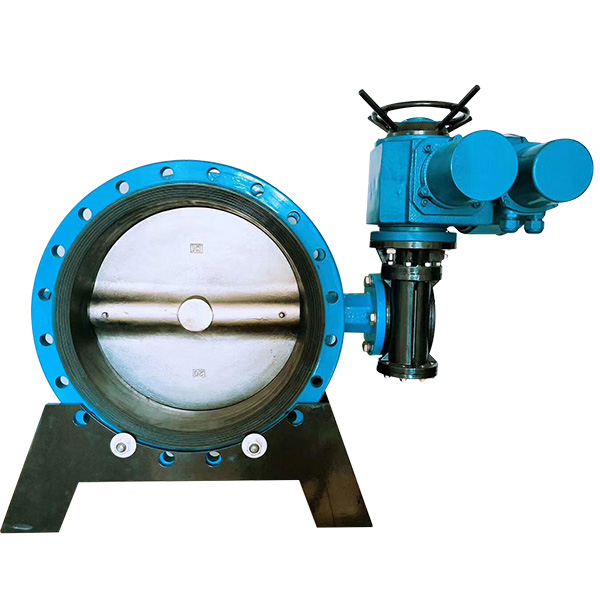

Product detail pictures:

Related Product Guide:

To create more benefit for buyers is our business philosophy; shopper growing is our working chase for 2020 High quality A105 Ball Valve - heavy type threaded 2-pc ball valve with ISO5211 pad BV-1000-01-02-N – Deye , The product will supply to all over the world, such as: Italy , Portland , Zambia , As a well educated, innovative and energetic staff,we are responsible for all elements of the research, design, manufacturing, sales and distribution. With studying and developing new techniques,we are not only following but also leading the fashion industry. We listen attentively to the feedback from our customers and provide instant communication. You will instantly feel our expertise and attentive service.

By Mary

from Finland

- 2018.04.25 16:46

By Mary

from Finland

- 2018.04.25 16:46

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.

By Gary

from Miami

- 2018.09.21 11:01

By Gary

from Miami

- 2018.09.21 11:01